How Labor Can Impact Large-Scale Pastry and Pizza Production

Pizza and pastry production is evolving rapidly, driven by changing consumer preferences and the need for efficient, large-scale manufacturing solutions. From gluten-free crusts to innovative recipes that serve as the next carriers of sauces and toppings, keeping up with the latest trends—and setting them—can result in significant profitability in large-scale pizza and pastry production.

Consider the profitability of pizza. Driven by several key factors—including high consumer demand, relatively low production costs, and significant scalability—pizza has been one of the biggest drivers of the foodservice economy since the onset of the COVID-19 pandemic. According to the 2024 Pizza Industry Trends Report, 66% of independent pizzeria operators are optimistic about the next 12-18 months, indicating strong market confidence. And while pizza is in demand in restaurants, particularly in the takeout and delivery space, it’s also popular as part of the take-home and take-and-bake industry. Pizza is also a segment driven by trends. Whether it’s the latest regional style or alternative, gluten-free crusts like those made with cauliflower, staying on top of trends and driving them can lead to excellent profit potential in today’s marketplace.

The production line is critical to the success of large-scale pizza and pastry manufacturing. However, the labor behind innovative machinery is just as important. Even though the human element might not include dough handling in high-volume industrial operations, it will still impact the success of the production line.

Why the People Behind Your Pizza Equipment Matter

After the COVID-19 pandemic, large-scale food manufacturers have become increasingly concerned about service availability and spare parts for their pizza production line equipment. Supply chain disruptions have made it challenging for manufacturers to source essential components, leading to potential delays in repairs and maintenance.

Staffing shortages have also become a significant issue in the pizza manufacturing industry. Skilled technicians and support personnel ensure the smooth operation of industrial baking equipment and pizza-making machines. Without adequate staff, companies struggle to address technical issues promptly, resulting in costly downtime and lost revenue.’

The importance of having a reliable team behind your pizza equipment cannot be overstated. The entire operation stops when any component of the production line fails, whether it’s the dough sheeter, pizza oven, or packaging machinery. This downtime translates into lost productivity, missed deadlines, and reduced revenue.

To mitigate these risks, it is essential to partner with a pizza equipment manufacturer that prioritizes customer support and invests in a skilled workforce. Look for companies with a proven track record of responsive service, a global network of technicians, and a commitment to keeping critical spare parts readily available. By choosing the right partner, you can minimize downtime, maximize efficiency, and ensure the long-term success of your pizza manufacturing operation.

The Value of Middleby Pizza and Pastry Equipment

Middleby’s pizza and pastry equipment offers unparalleled value to industrial food processors through its global partnerships, diverse product range, dedicated workforce, and commitment to innovation. With 28 brands, including Stewart Systems and Baker Thermal Solutions, Middleby sources the best people, partners, and technologies worldwide to deliver cutting-edge pizza production line and industrial baking equipment.

Global Partnerships

Middleby’s global reach allows them to identify and collaborate with top talent, sourcing partners, and brands worldwide. This extensive network enables the company to bring together the most advanced pizza manufacturing equipment and expertise to meet the evolving needs of the industry.

Diverse Product Range

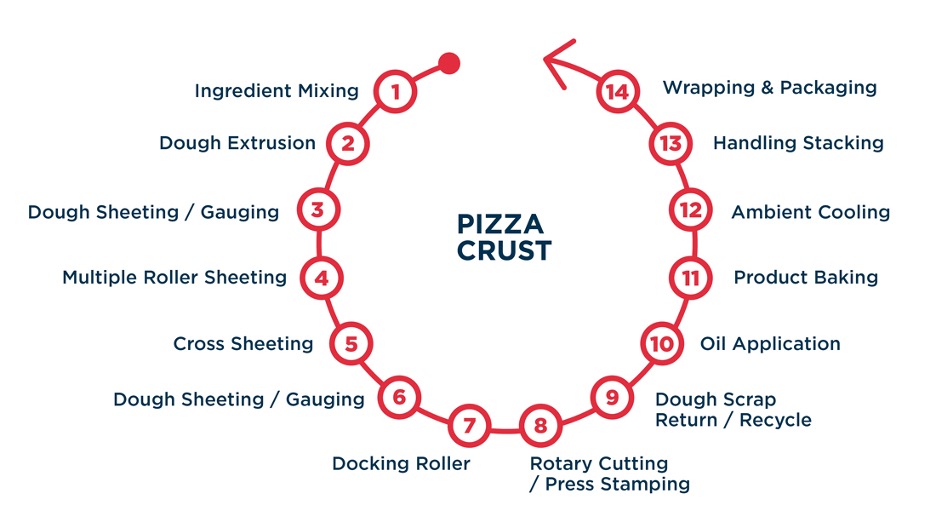

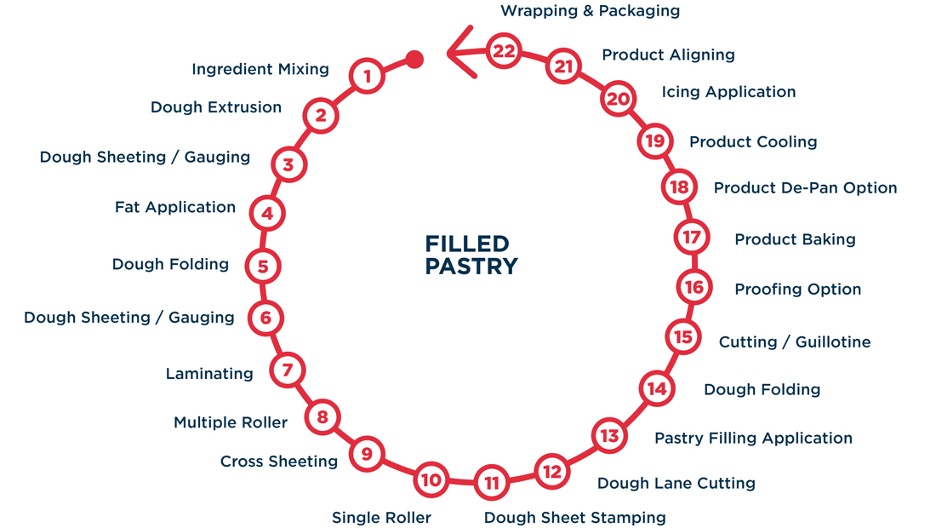

Middleby’s comprehensive portfolio covers every aspect of the pizza and pastry production process, from mixing and proofing to baking, cooling, and packaging. The company’s equipment can handle various products, from hearthstone pizzas and par-baked crusts to mass-produced wood-fired offerings. Middleby also assists semi-industrial operators looking to scale up to fully industrial operations, working closely with customers to predict future growth and set up equipment infrastructure that accommodates expansion without requiring additional purchases.

Powered by People

Our skilled and dedicated workforce drives Middleby’s success. We cross-train personnel on various equipment, ensuring a well-rounded and knowledgeable team. This commitment to continuous service and support helps maintain a solid team of experts to assist customers. The company’s strategically located service centers enable fast and cost-effective support, while their 24/7 hotline provides customers with direct access to human support whenever needed.

Powered by Innovation

Innovation is at the core of Middleby’s approach to pizza and pastry equipment. The company leverages advanced technologies like Real Wear remote service, which includes a headset and video camera, to facilitate remote service and troubleshooting. This technology allows service agents to view issues remotely, minimizing downtime and enhancing efficiency. Middleby offers Real Wear as an option at the time of purchase or as an add-on later, providing flexibility to customers.

In addition to technological innovations, Middleby supports customers through classes, seminars, and its annual baking summit. The company also invites customers to visit one of our Bakery Innovation Centers in Texas, India, and Spain, where we can experience firsthand the latest pizza and pastry production equipment advancements.

Topics

- Bakery ()

- Bacon ()

- Sous Vide ()

- Poultry ()

- Hot Dog and Sausage ()

- See All Topics