Meeting Global Demands with Artisan Bread at Scale

Consumers everywhere are reaching for better bread. In both the U.S. and Europe, the demand for high-quality, natural, artisan-style breads is climbing fast.

The global artisanal bakery market was valued at nearly USD 95 billion in 2022, and is projected to grow more than 5% annually through 2030, with Europe already holding over 30% of that share. In North America, artisan bakery sales are expected to rise from USD 5.1 billion in 2023 to nearly USD 7.8 billion by 2032. Consumers are choosing breads that taste better, use natural ingredients, and echo traditional methods, whether that’s a baguette in Paris or a sourdough loaf in San Francisco.

For bakeries, the challenge is translating artisan quality into profitable, repeatable production. That’s where equipment, engineering, and process design make all the difference.

What Makes Artisan Bread Different from Standard Loaves?

Artisan bread differs from standard tin loaves or buns in three ways:

- Long fermentation with sourdoughs or biga doughs.

- High hydration levels, often 65–85%.

- Product diversity available in many shapes and sizes; handcrafted appearance has an open crumb with a robust flavor.

At industrial scale, these processes introduce complexity. Traditional equipment designed for high-volume tin bread won’t deliver the same texture, crust, or consistency required for artisan products. Instead, bakers need specialized systems that respect the dough while streamlining throughput.

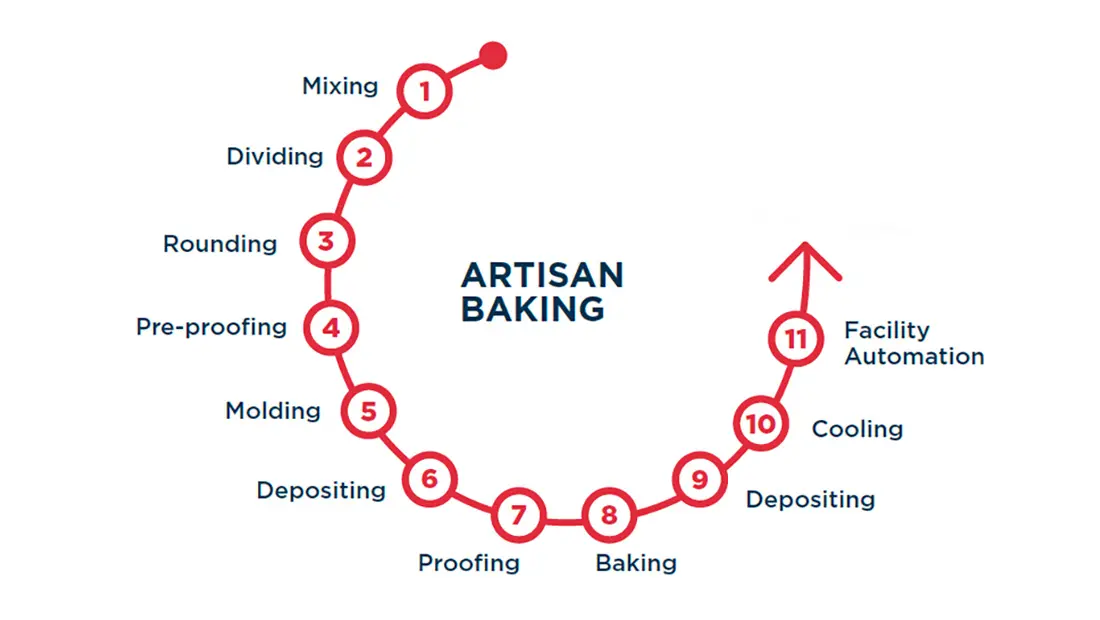

The Key Stages in Artisan Bread Production

The industrial artisan breadmaking process isn’t that dissimilar from local, small-scale production. Many of the same processes must be considered. Here are a few critical steps to create artisan bread at scale.

Dividing

Dough begins in mixers, then moves into dividers that portion accurate weights. Stress during dividing makes intermediate proofing essential to relax the dough and preserve cell structure. Middleby’s Glimek or GBT offer options for small or large volumes, with models capable of handling hydration up to 85% and a capacity up to 10.000 pc/h, depending on the weight of each product

Pre-Fermentation & Proofing

Intermediate proofers allow the dough to recover after dividing. Later, final proofers prepare loaves for the oven. Consistency here impacts bake quality, shape, and volume. Middleby solutions balance flexibility with precision timing, keeping dough relaxed and production on track.

Molding & Sheeting

Depending on the product (round loaves, long baguettes, or coiled sheets) lines can adapt with molder or sheeting equipment. Glimek and GBT systems make changeovers simple, shifting from 200-gram rolls to 800-gram loaves in minutes.

Baking

This is where artisan quality comes alive. Middleby’s Sveba Dahlen or GBT ovens offer modular zones where bakers can adjust heat and steam chamber by chamber. That control means the same recipe can yield a baguette with a crisp, dark crust or a loaf with a lighter, softer finish without sacrificing throughput.

Cooling & Beyond

Post-bake systems from brands like Baker Thermal Solutions and Scanico integrate cooling, chilling, and freezing, enabling full-line continuity and food safety.

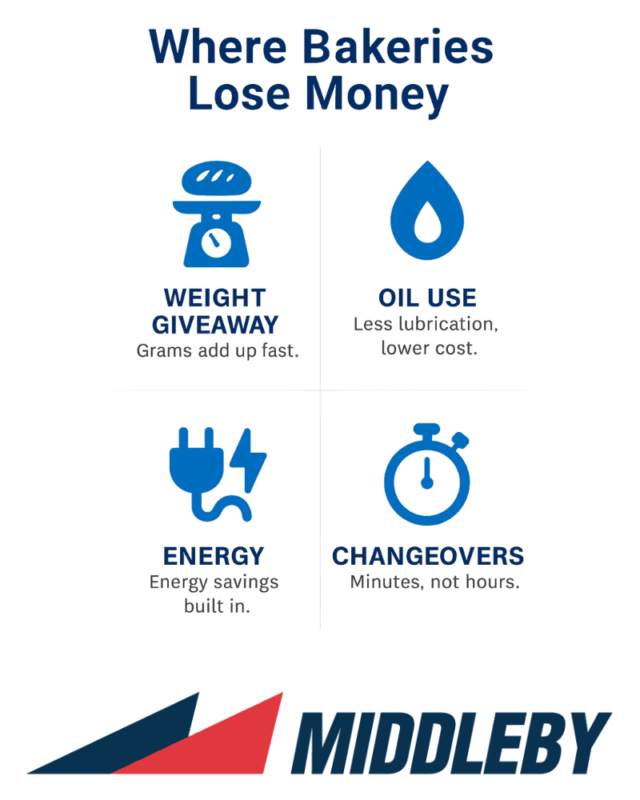

Where Do Industrial Artisan Baking Operations Lose Money?

Even small inefficiencies can become major cost drains at scale. At 10,000 loaves per hour, a few grams of weight giveaway quickly translates into tons of lost product each year.

Lubrication oil is another hidden cost, but the right divider, for example, can help reduce oil costs. Energy is also a major driver, and ovens can lower kWh usage while still delivering artisan quality. Finally, fast changeovers on dividers and proofers mean bakeries can switch SKUs in minutes instead of losing valuable production time.

Middleby’s Answer: Tailored, Turnkey Solutions

Middleby’s advantage lies in its breadth. Few providers can match the range of specialized equipment across the artisan line. Brands like Glimek, Sveba Dahlen, Escher mixers, and Baker Thermal Solutions integrate seamlessly into complete turnkey systems. For each step, Middleby engineers analyze recipes, hydration levels, and target volumes, then design a line that balances artisan quality with industrial efficiency.

Whether a bakery is scaling a single sourdough line or running a portfolio of baguettes, rolls, and loaves, Middleby provides the flexibility to adapt—and the expertise to prove ROI before installation.

Middleby uses its engineering and technology to codify the artisan process, transforming the intuitive skills of a master baker step by step into a reliable, scalable automated system.

Beyond the Bake: Support and Service

Equipment is only part of the story. Middleby customers receive:

- On-site training immediately after installation.

- Remote troubleshooting, where engineers can access systems online to diagnose and resolve issues quickly.

- Service and maintenance support to maximize uptime and extend equipment life.

For bakeries making high-value investments, these services are often as important as the equipment itself.

See It in Action by Visiting the Middleby Bakery Innovation Center

The best way to understand artisan bread at scale is to test it yourself. At the Middleby Bakery Innovation Center, bakers bring their recipes, run them through complete lines, and refine processes with expert guidance. It’s the ideal environment to see how Middleby solutions turn artisan methods into profitable production.

Topics

- Bakery ()

- Case-Ready ()

- Bacon ()

- Sous Vide ()

- Poultry ()

- See All Topics