Smaller Footprint, Bigger Payoff: Smarter Case-Ready Portioning

When margins are tight, “close enough” turns into giveaway, rework, and waste. The fastest way to protect profit in case-ready (portioning) is to control variation at the slice, making it as precise as possible. That’s the Middleby approach: a press-scan-portion core engineered solution for accuracy, embedded in a fully integrated line that reduces assets, labor, and risk end-to-end.

The Business Case Behind Case-Ready

Operators know the math: on premium cuts, a point or two of giveaway is real money. Add first/last slice losses, cherry-picking at retail due to uneven packs or product with cut marks, and manual touches at loading, and you’re paying for variability multiple times. The countermeasure is a tightly coupled sequence that stabilizes the product, reads geometry, cuts to spec, and then hands off to packaging without friction.

Press, Scan, Portion

Thurne’s portioning system is built to make on-spec performance repeatable:

Crust freeze for control. A light perimeter crust creates the rigidity needed for clean, repeatable slicing without freezing the core, preserving color and preventing ice-crystal damage.

In-machine pressing. Pressing happens inside the portioner, so the primal goes straight to the cutting head—no transport lag, no relaxation, no shape drift.

3D scanning + servo control. The system weighs, shapes, and scans each primal, then calculates the cut plan slice-by-slice. Servo feed advances at the thickness required to hold target weights, minimizing giveaway and reclaiming first and last slices into saleable product.

Clean-face cuts. Blade mechanics and motion deliver an even surface without visible striations, improving retail appeal at the shelf.

The bottom line is a design that targets less than one percent giveaway and nearly 100 percent usable yield (including first and last slices) with consistency at throughput.

Smaller Footprint, Fewer Assets

Because pressing is integrated into the portioner, you remove a standalone press from the line. That shrinks the footprint, simplifies controls and communications, and reduces the number of critical assets for commission, service, and stock spares. The results include faster installations, fewer interlocks, and less troubleshooting, all factors that can be reflected quickly in profitability reporting.

Formats That Remove Labor

Beyond singles, the Thurne system can generate various formats (shingled groups, layout packs, twin-packs, stack-packs, hybrids), allowing trays to be loaded closer to the finished presentation. That’s fewer touches, less variability, and higher paid-weight at the package level, especially useful where staffing is tight or turnover is high.

Continuous sanitation matters when uptime is money. Optional VYV antimicrobial lighting operates 24/7 to inhibit surface microorganisms and is designed to be operator-safe, distinct from typical UV/blue-light approaches. During daily cleaning, tool-less teardown is prioritized where possible; components move on hygiene trolleys while frames are washed in place. Net result: more productive hours in a two-shift schedule.

The Full Middleby Line: One Partner, One Plan

Portioning is only as strong as its handoffs. Middleby integrates a complete case-ready line with one project manager, so upstream/downstream communication and service aren’t your problem. Our goal is to be a comprehensive solutions provider, delivering the highest profit margins possible by implementing the following brands:

- Scanico crust freezers establish perimeter rigidity without full freeze, ideal for pre-portioning conditioning.

- Thurne does the press-scan-portion heavy lifting and generates pack formats for labor reduction.

- Loading through robotic pick-and-place or conveyorized solutions keeps presentation consistent.

- Packaging via RapidVisionPak thermoformers or CV-TEK overwrap systems, including bulk MAP where multi-tray modified-atmosphere bags are the best shelf-life lever for your market.

- Sanitation with Colussi Ermes automated systems; interleaving via Pacproinc when paper or film layers are required.

That stack turns multi-vendor coordination into a single accountable plan—fewer handoffs, fewer surprises, faster time to steady state. For context, Middleby’s own case-ready application hub highlights Thurne as the centerpiece brand within the offering.

Retail Sell-Through and Sustainability

Uniform thickness and clean-face cuts reduce cherry-picking, so the “good-looking” packs don’t sell first while the thin or fatty packs age out. Better sell-through means less food waste and packaging waste, fewer rewraps, and fewer miles moving unsold product.

Fixed-Weight and Catch-Weight Without the Hand-Wringing

Whether you’re running fixed-weight for strict spec or catch-weight for consistent thickness with weigh-price labeling downstream, the same fundamentals apply: stabilize, read, and cut. The benefit of precise thickness control is evident in both on-weight percentages and giveaway reduction, as well as in improved presentation.

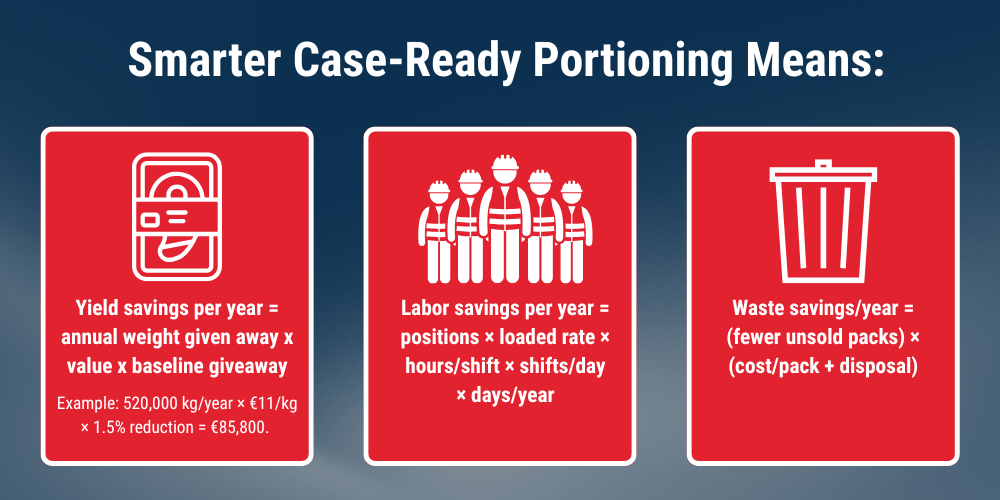

A Simple ROI Snapshot:

Why now?

Protein pricing volatility (particularly beef) pushes consumers toward pork and chicken. That puts even more pressure on yield control today and positions you to capture outsized ROI when premium cuts normalize. Meanwhile, integrated lines reduce commissioning risk and accelerate time to value, two things that matter most in a capex cycle.

We can help deliver solutions that meet these demands, and we often suggest starting with a case-ready discovery session at the Middleby Protein Innovation Center, or schedule a full-line consult. We’ll align around your SKUs, pack formats, and market (fixed-weight, catch-weight, MAP strategy), then prove out the gains on your terms.

Experience innovation firsthand. Witness the latest advancements in bacon processing technology. Schedule your visit to the Middleby Protein Innovation Center now!

Topics

- Bakery ()

- Case-Ready ()

- Bacon ()

- Sous Vide ()

- Poultry ()

- See All Topics