How New Technologies Can Enhance Old Traditions in the Salami and Dry Cure Industry

The salami and dry-cured meats industry has a rich history steeped in old-world traditions passed down through generations. These time-honored techniques are critical for producing the distinctive flavors and textures that define high-quality salami and other dry-cured meats like pepperoni, prosciutto, boneless ham, and others. As consumer demand grows and food safety regulations become more stringent, though, meat processors face increasing challenges in maintaining these traditions while keeping up with production demands.

New technologies are emerging that can help salami and dry cure producers overcome these hurdles without compromising quality or tradition. From automated meat processing lines that enhance throughput and consistency to advanced remote assistance capabilities that enable 24/7 support from equipment providers, Middleby is a solutions provider committed to transforming the industry.

For producers, implementing cutting-edge factory automation systems and partnering with leading solutions and systems providers like Middleby can allow dry-cured meat makers to uphold their cherished craftsmanship while improving safety, efficiency, and profitability.

The Challenges of Salami and Dry Cure Production

Salami and dry-cured meat producers face numerous challenges in their quest to deliver high-quality products consistently. The most important aspect is undoubtedly the product itself—respecting the old-world recipes, methods, and traditions passed down through generations. However, it’s possible to respect these time-honored processes while still enhancing throughput and efficiency in production. As with any recipe, proper processing is key along the production line to achieve an optimal product.

Salami and dry-cured meat producers face numerous challenges in their quest to deliver high-quality products consistently. The most important aspect is undoubtedly the product itself—respecting the old-world recipes, methods, and traditions passed down through generations. However, it’s possible to respect these time-honored processes while still enhancing throughput and efficiency in production. As with any recipe, proper processing is key along the production line to achieve an optimal product.

One key challenge is maintaining consistent quality throughout the year. While the definition of “quality” can be subjective, consistency is one important aspect of quality that cannot be argued. For producers, the goal is always to create a consistent product, though it’s not always a hassle-free task due to the characteristics of the raw ingredients used. Pork, in particular, can vary seasonally. For example, pigs tend to be fatter during certain times of the year, which requires adjustments in processing to maintain consistency. There are other variables to consider, as well, and proper equipment and processes can play a crucial role in addressing them. Consider other seasonal variations like weather and location. Production equipment should be adaptable to accommodate differences in raw materials and environmental conditions like weather and location. When operators truly control the entire production process, it allows for necessary adjustments to be made promptly.

Sanitation is another critical challenge in salami and dry-cured meat production. Equipment must be regularly cleaned and sanitized to prevent contamination and ensure food safety. Failure to maintain proper sanitation can lead to costly product recalls and damage a brand’s reputation.

Implementing the right technologies and partnering with knowledgeable solutions and systems providers like Middleby can help producers navigate these challenges more effectively. By leveraging innovative solutions that enhance consistency, efficiency, and food safety, producers can uphold salami-making’s cherished traditions while meeting modern production demands.

The Importance of Food Safety

Food safety is of utmost importance in the salami and dry-cured meat industry. Dry-cured meats can be susceptible to contamination by various pathogens if proper precautions are not taken during processing and storage. Listeria monocytogenes, for instance, is a significant concern in salami and meat production due to its ability to thrive in warm, humid environments. Manufacturers should be aware of its prevalence and prepare accordingly.

Food safety is of utmost importance in the salami and dry-cured meat industry. Dry-cured meats can be susceptible to contamination by various pathogens if proper precautions are not taken during processing and storage. Listeria monocytogenes, for instance, is a significant concern in salami and meat production due to its ability to thrive in warm, humid environments. Manufacturers should be aware of its prevalence and prepare accordingly.

Processing equipment should be designed for easy cleaning and sanitation to minimize the risk of contamination. Smart designs that expose all surfaces for thorough sanitization are crucial. Regular inspection and daily cleaning of factory equipment are essential to maintaining a hygienic production environment. Careful monitoring of airflow and humidity levels is critical during the aging process. Inadequate control of these factors can create conditions conducive to the growth of harmful bacteria.

Product recalls due to contamination can have devastating financial consequences, potentially costing millions of dollars. Therefore, investing in proper food safety measures, including advanced equipment and rigorous hygiene protocols, is not only a moral obligation but also a sound business decision for salami and dry-cured meat producers. By prioritizing food safety at every stage of production, from raw material selection to final packaging, manufacturers can uphold the rich traditions of salami-making while ensuring the well-being of their customers. Embracing innovative technologies and best practices in sanitation and quality control is key to producing safe, high-quality cured meats that consumers can enjoy with confidence.

Reducing the Impact of Labor Challenges

The salami and dry cure industry has traditionally been a labor-intensive sector, with many processes relying on manual labor. Hanging salami by hand, for instance, consumes vast amounts of time and labor, leading to backbreaking work that impacts profitability. However, new innovations in automation are helping to address these labor challenges and make processes easier.

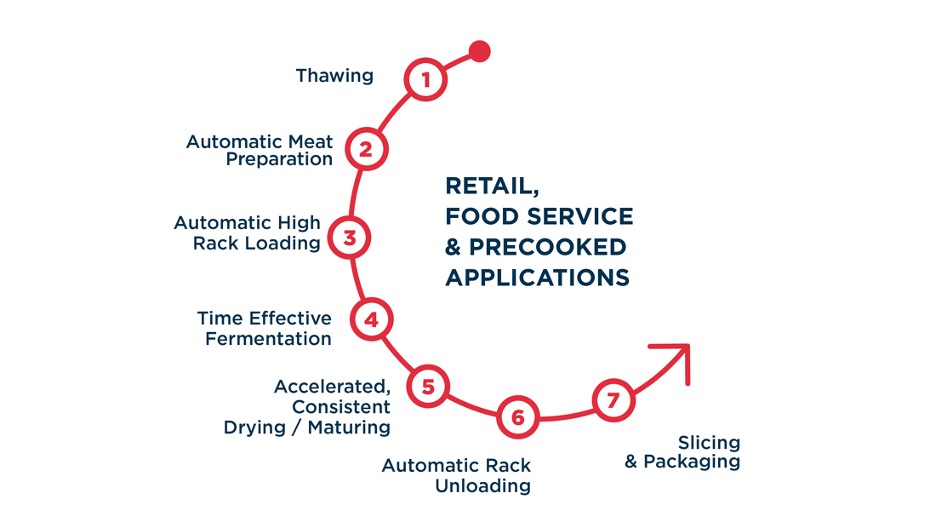

Automated salami and dried meat processing equipment is transforming the industry. Automated Guided Vehicles (AGVs) are a prime example of how automation can streamline operations. These AGVs move racks around the factory with tons of salami hung above, allowing for more efficient use of space. The racks can go higher than traditional methods, meaning more product per footprint or potentially smaller workspaces that can produce higher volumes per square foot.

AGVs also provide complete visibility into data points in real-time by tracking produce movement throughout the factory. This is particularly important when salami loses weight due to water loss and becomes safe and ready for processing and shipping. Waiting for the product to reach the desired weight can lead to lost revenue, but AGVs can help weigh racks in real-time, ensuring operations know exactly when the product is ready. In terms of yield, even a small change of 25 grams per leg can add up to millions when scaled across an entire production facility. By automating manual, repetitive tasks, salami and cured meat producers can reduce their reliance on labor, improve efficiency, reduce or eliminate errors, and boost profitability. As the industry evolves, embracing automation will be key to overcoming labor challenges and ensuring long-term success.

The Power of Middleby Salami and Dry Cure

Partnering with the Middleby Corporation offers numerous advantages for salami and dry-cured meat producers. Middleby allows collaboration with other industry segments, ensuring that end users have a single source for all their equipment needs and a unified point of responsibility. This streamlined approach simplifies the process for producers and provides peace of mind.

Middleby’s commitment to customer support is unparalleled. We offer comprehensive training, along with conveniently scheduled visits, to ensure that equipment is operating at peak performance. In addition, Middleby provides 24/7 remote support, enabling real-time monitoring of equipment from anywhere in the world. This level of support is particularly valuable when staff turnover occurs, as Middleby can provide training during installation and whenever new team members are brought on board.

Middleby’s remote capabilities extend beyond training and support. Middleby can conduct system check-ups remotely and offer guidance to optimize performance. This proactive approach helps identify potential issues before they become significant problems, minimizing downtime and maximizing efficiency.

By connecting all the dots in the production process, Middleby empowers salami and dry-cured meat producers to have better control over their operations. Our innovative solutions are designed to improve productivity, expand capacity, maximize hygiene, optimize resource consumption, increase profitability, and maintain consistency. This level of visibility and control is crucial in an industry where small details or changes can lead to significant gains or losses.

Experience innovation firsthand. Witness the latest advancements in meat processing technology. Schedule your visit to the Middleby Protein Innovation Center now!

Topics

- Bakery ()

- Bacon ()

- Sous Vide ()

- Poultry ()

- Hot Dog and Sausage ()

- See All Topics