Maximize Productivity with Advanced Bacon Processing Equipment

Bacon processing equipment plays a crucial role in maximizing productivity and ensuring product quality in a high-demand landscape. For manufacturers, the challenges continue to be adhering to consumer preferences, maintaining quality, and remaining profitable in a marketplace currently challenged by labor concerns. To counter these issues, advanced bacon processing solutions offer manufacturers the opportunity to streamline operations, reduce waste, and meet the growing market demands with precision and consistency.

By examining the critical components of bacon processing and manufacturing, bacon processing equipment manufacturers like Middleby can better prepare operators with solutions to enhance processing capabilities.

The 3 Key Types of Bacon Processing

The bacon manufacturing industry primarily focuses on three key types of bacon processing: retail, foodservice, and pre-cooked. Each type caters to specific market demands and requires tailored equipment solutions.

Retail Bacon Processing with Middleby

Retail bacon, intended for residential use, typically comes in 12-16 shingle packs with a thick paper and a window for product visibility. Traditional retail bacon production involves turning the product 180 degrees on the production line to accommodate these packaging requirements. In many facilities, this process is conducted by a robot that picks up and turns each bacon pack. The issue with this is that when it gets cold, ice crystals compromise the shingle packs when turning, and when bacon warms, it becomes moist and can stick to temperature-sensitive robotics. Instead, Middleby developed a process to animate this rotation right on the line itself.

Foodservice Bacon Processing with Middleby

Foodservice bacon undergoes raw bacon production, utilizing the same raw materials through the presser, slicer, and layout process. Slicing is graded based on fat content (lean/fat percentage), thickness, and weight using Thurne Two slicers. Thurne One slicers further determine the muscle distribution of the protein for optimal results.

Pre-Cooked Bacon Processing with Middleby

Pre-cooked bacon, a younger but rapidly growing market, is trending, especially in restaurants. Middleby Food Processing’s bacon division leads the pre-cooked bacon industry, supplying over 70% of the market with manufacturing equipment. Middleby handles over 50 pre-cook bacon lines in North America, each producing over 1 million slices daily.

The Role of Equipment in Industrial Bacon Manufacturing

Middleby Food Processing offers a complete suite that covers the entire bacon manufacturing process, providing turnkey capabilities unmatched by any other company in the industry.

Optimizing Bacon Belly Preparation

Bacon belly preparation has a significant impact on the final product quality. The process involves sorting bellies by weight and thickness, which results in more uniformly processed bacon. Middleby’s technologies automate this labor-intensive process, potentially reducing the plant labor force by 25% to 60%.

After sorting, the bellies undergo a flow-through process capable of handling up to 20,000 pounds per hour and move through a water jet and sorter before entering the injection and vacuum tumbling stages.

Flattening curled bellies is crucial for optimal slicing. This can be done by water jetting smoked bellies after pressing or flattening them in a press before cutting. The challenge lies in pulling folded-over flaps past 90 degrees to ensure they lay flat during pressing.

Revolutionizing Bacon Slicing Techniques

Middleby’s innovative slicing technologies revolutionize bacon processing, delivering superior results compared to traditional methods. Their slicers, such as the Thurne One and Thurne Two, provide unprecedented yield and throughput while considering cost of ownership for retail and foodservice producers. Servo-controlled tracks, small blade technology, and cut face vision enable consistent performance, combining high throughput, maximum first-time on weight, and minimal giveaway.

Middleby’s slicers offer better control of thickness and weight, resulting in a 10% higher yield compared to bandsaw slicers. Bandsaws often lose mass when cutting via dust and small particulates, and require more maintenance than Middleby’s options.

Maximizing Yield and Reducing Waste in Bacon Processing

After slicing, bacon enters the lay-down or shingling process for retail packaging. For pre-cooked options, TurboChef ovens take efficiency to the next level by combining advanced microwave, hot air convection, and steam heating methods to deliver perfectly cooked results. Equipped with a durable stainless steel belt and customizable 16kW microwave energy zones, these ovens ensure precision and consistency for large-scale operations.

Once cooked, bacon is sheeted and stacked for packaging using Middleby’s RapidVisionPak automatic stacking technology. This innovative system streamlines operations, reducing the need for 6 to 10 workers per shift. Paired with TurboChef’s automated cleaning features and SCADA-compatible controls, processors can maximize output while minimizing labor and maintenance challenges.

Middleby Food Processing offers a complete suite that covers the entire bacon manufacturing process, providing turnkey capabilities unmatched by any other company in the industry. This comprehensive approach maximizes efficiency and reduces waste throughout the production line.

Efficient Packaging Solutions for Various Bacon Products

Middleby also provides comprehensive packaging solutions for various bacon products. Their comprehensive capabilities cover the entire bacon manufacturing process, from belly preparation to final packaging. No other company in the industry offers such a complete suite of equipment and services.

By implementing Middleby’s efficient packaging solutions, bacon manufacturers can significantly reduce labor costs, improve product consistency, and increase overall productivity. These advanced technologies ensure that bacon products are packaged quickly, safely, and with minimal waste.

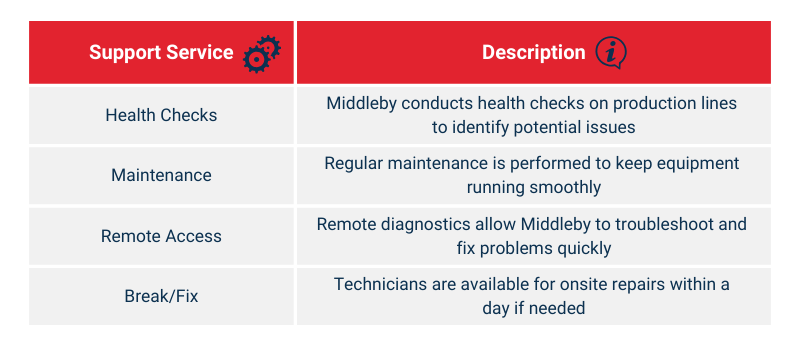

Bacon Manufacturing Equipment Support from Middleby

Middleby offers comprehensive support for its bacon manufacturing equipment. It provides health checks on production lines and performs maintenance to ensure optimal performance. With remote access to bacon equipment, Middleby has an 85% success rate in diagnosing and fixing issues before they escalate into major problems.

In case of break/fix issues, Middleby technicians can be onsite within a day to resolve the problem. However, their primary focus is on preventative diagnostics to minimize downtime and maintain high productivity levels.

By offering these comprehensive support services, Middleby ensures that its bacon manufacturing equipment operates at peak efficiency, reducing waste and maximizing customer productivity.

Experience innovation firsthand. Witness the latest advancements in bacon processing technology. Schedule your visit to the Middleby Protein Innovation Center now!

Topics

- Bakery ()

- Case-Ready ()

- Bacon ()

- Sous Vide ()

- Poultry ()

- See All Topics