The Essentials of Poultry Processing Equipment

Poultry processing equipment plays a crucial role in the global food industry. As demand for poultry products continues to grow, efficient and reliable machinery has become essential to meet production needs. From slaughtering to packaging, modern poultry processing plants rely on specialized equipment to handle each step of turning live birds into consumer-ready products.

The Nuances of the Commercial Poultry Industry

The commercial poultry industry has seen remarkable growth over the past 50 years, driven by scientific research, integration of various segments, and innovation. Advances in nutrition, disease control, genetics, technology, and management techniques have enabled the industry to produce poultry meat and eggs more efficiently.

While burger prices often set consumer expectations for meat costs, poultry follows a different path. As the least expensive protein, poultry is a staple across cultures with fewer restrictions because there are generally no cultural or religious restrictions on its consumption. This is why chicken production is increasing in places like the Middle East.

There are also challenges with poultry production, as it is highly sensitive to external factors like disease and disasters. It takes around 39 days from egg to harvest, but the process is labor-intensive and challenging to automate. Supply chain costs, including electricity and energy, feed, and labor, heavily influence the industry. COVID-19 highlighted the reliance on manual labor, causing significant disruptions. Despite these challenges, poultry production remains highly adaptable, recovering in days rather than years due to its rapid production cycle. This adaptability has helped fuel the industry’s expansion.

Poultry processing equipment plays a crucial role in transforming live birds into consumer-ready products. From slaughtering to packaging, modern poultry processing plants rely on specialized machinery to handle each step efficiently. Automation and advanced poultry processing solutions are helping the industry meet production needs while addressing labor challenges. Companies like Middleby are developing innovative chicken processing plant equipment and poultry packaging equipment to improve efficiency, food safety, and product quality in processing facilities worldwide.

The Processes of Poultry Processing

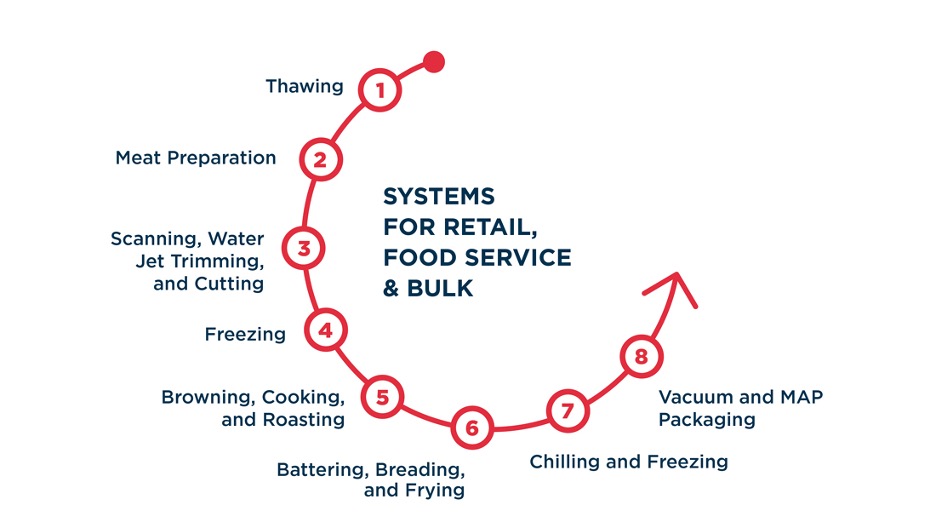

Poultry processing can be divided into two key stages: primary and secondary. Primary processing involves transforming live chickens into consumer-ready products, including deboning, filleting, portioning, and packaging. Secondary processing adds value by utilizing the entire bird, often creating new products like chicken nuggets or pre-cooked meals.

For poultry equipment, adaptability is crucial—machines must handle varying sizes of product, from chickens to turkeys. With the goal of increasing production while reducing labor, precise portioning and uniformity are essential, especially for restaurants and QSRs, where consistency is critical.

Commercial Poultry Processing with Middleby

The main supply chain considerations in poultry processing are the costs of energy, feed, and labor. While feed prices remain out of our control, Middleby Food Processing delivers advanced solutions to help reduce labor and energy costs—key factors in improving efficiency.

Labor represents a significant cost in the poultry industry, especially in processes like extracting meat from bones, where human precision often surpasses automation. However, Middleby’s multi-brand approach focuses on enhancing automation without sacrificing quality. By combining brands and technologies across the processing line—from portioning to marination, batter frying, and breading—Middleby offers a full-line solution that minimizes labor dependency while boosting productivity.

Energy efficiency is equally crucial. Middleby addresses this with innovations that reduce the number of motors required in production lines, cut down product waste, and improve gear efficiency. Take the ThoroughBreader™ breading system, for example. It reduces flour waste, which not only saves money but also cuts down on labor needed for cleanup.

Furthermore, Middleby’s frying systems, with Filtration Automation technology, extend the lifespan of frying oil up to five times, helping processors reduce waste and energy use. By focusing on sustainability, we help clients lower their carbon footprint while increasing operational efficiency. Filtration Automation, known for Micron-Pro brand high-capacity oil management systems, gives operators the benefits of labor savings, improved fryer performance, and opportunities for significant cost savings in poultry production.

From reducing labor costs to promoting sustainable practices, Middleby Food Processing continues to drive automation and energy-efficient solutions that help poultry producers meet the demands of a changing global market.

Working with Middleby Food Processing Means Comprehensive Post-Sale Support

At Middleby Food Processing, our commitment doesn’t end after the sale. We understand that time is money, which is why we provide robust post-sale support designed to keep your operations running smoothly and efficiently.

Our Customer Experience Group is dedicated to empowering our clients through hands-on training, ensuring they can operate independently with confidence. As it becomes increasingly difficult to find skilled maintenance and service personnel, Middleby steps in to help bridge the gap. We use advanced technology like remote access and cameras to troubleshoot issues quickly, minimizing downtime and resolving problems without the need for an on-site visit.

With Middleby’s support and technology, your team can address maintenance needs faster, allowing you to get back online quickly and maximize productivity.

Experience innovation firsthand. Witness the latest advancements in poultry processing technology. Schedule your visit to the Middleby Protein Innovation Center now!

Topics

- Bakery ()

- Bacon ()

- Sous Vide ()

- Poultry ()

- Hot Dog and Sausage ()

- See All Topics