Maximizing Efficiency and Consistency with Commercial Sous Vide Processing

Sous vide cooking is most often associated with fine dining, though many foods in all types of restaurants might utilize the commercial sous vide cooking process. The reason is simple. Sous vide cooking provides a host of benefits that can help achieve food safety, consistency, and enhanced food preservation.

In terms of manufacturing, commercial sous vide production for foodservice and restaurants is the largest application, outpacing retail applications by about four to one. Products like beans, cooked at large-scale plants and reheated in restaurants such as Chipotle, illustrate how sous vide cooking can streamline operations, eliminating in-house cooking while delivering a consistent and safe product. Even traditionally tricky items like burgers are being sous-vide-cooked to perfection, needing only a final reheat at the point of service.

Culinary precision and consistency are as critical for large-scale commercial sous vide applications as fine dining. Sous vide not only enhances product quality but also ensures the ability to design and produce the best possible product for customers across various markets.

How Commercial Sous Vide Works

The magic of sous vide cooking lies in its simplicity and precision. At its core, the process involves sealing food products in vacuum-sealed bags and immersing them in water at precisely controlled temperatures. Unlike traditional cooking methods, where heat transfer through air can be inconsistent, water is a more efficient conductor of heat. This allows for more even cooking and prevents overcooking—a key benefit for high-volume operations.

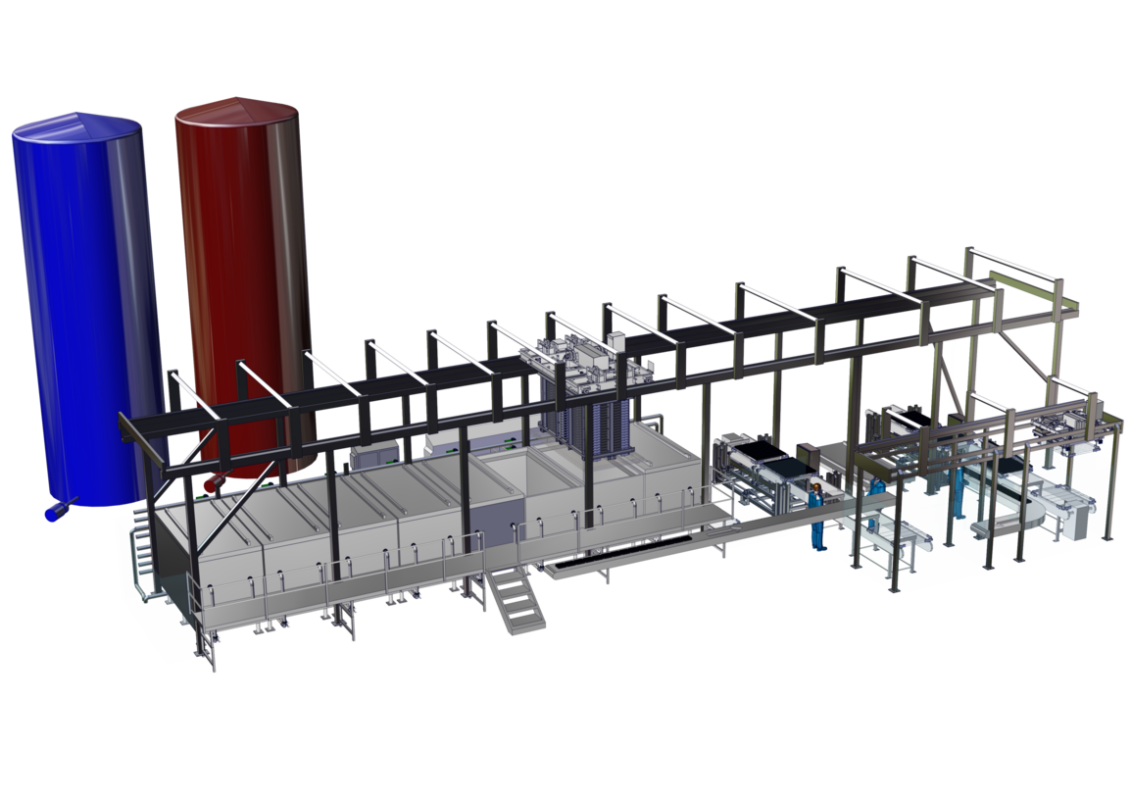

In commercial sous vide systems, foods are placed into bags and loaded into baskets. These baskets are then submerged into water processing tanks, where the cooking process can last anywhere from two to 48 hours, depending on the product being cooked and the desired final result. After the cooking phase, the system automatically chills the product using chilled water. It can be frozen to adapt with logistics.

This fully automated process moves the water, not the product, enhancing efficiency by minimizing handling and ensuring that each batch is processed under optimal conditions. With such precise control, the system guarantees uniform results, delivering consistently cooked products time after time.

Promote Food Safety with Commercial Sous Vide Cooking

Food safety is always the top priority in any food manufacturing operation, and commercial sous vide excels in this area by reducing the need for raw food handling. Foods are cooked in sealed bags during production and only require reheating at the final destination, whether a restaurant or another foodservice venue.

This process significantly minimizes handling raw food, particularly meats, which are often a source of foodborne illnesses. In addition, sous vide cooking can help operations efficiently meet HACCP (Hazard Analysis Critical Control Point) compliance standards at both the point of production and the point of processing in the restaurant.

Create Consistency While Increasing Restaurant Efficiency

Maintaining consistency across multiple locations is essential in today’s chain restaurant landscape. Commercial sous vide cooking offers an easy way to provide that consistency because products are pre-cooked using precise temperature control and automation. Whether a restaurant serves medium-rare burgers or delicate, clean-label products, the uniformity achieved through sous vide cooking ensures that customers enjoy the same experience no matter where they dine.

For operators, commercial sous vide cooking reduces the need for skilled labor in the kitchen, as much of the cooking process occurs in the factory. With pre-cooked ingredients, reheating, rethermalizing, and finishing become the priority. This reduces cooking times and improves quality control, enhancing both operational efficiency and customer satisfaction.

Gain Greater ROI Through Food Preservation

One of the major advantages of commercial sous vide cooking is its ability to extend the shelf life of food products. When fresh, sous vide products have a shelf life of 40-90 days. When combined with complementary technologies like blast chilling or shock freezing, sous vide-cooked foods remain secured for at least a year. This extended shelf life not only ensures that food remains high quality for longer but also reduces food waste, leading to greater profitability.

Long shelf life, paired with the ability to lock in flavor and nutrients, makes sous vide a cost-effective solution for food manufacturers. Whether the final product is destined for foodservice or retail, the benefits of extended preservation mean less spoilage and fewer costs associated with unsellable goods.

Commercial Sous Vide with Middleby

Middleby offers advanced sous vide processing solutions designed to accommodate the needs of high-volume food manufacturers and foodservice operations. Their systems, such as the Thermix™ and Flowmatix™ can handle a wide range of outputs, from 200 pounds per hour in smaller operations to as much as 10,000 pounds per hour per line in large-scale plants. These systems provide complete automation, streamlining the entire cook-and-chill process without requiring significant manual intervention.

The Thermix™ system, known as “The Original Sous Vide Cooking System,” is particularly suited for facilities needing consistent, high-quality results. It features continuous water circulation, which ensures uniform cooking/chilling and optimal heat transfer. This method maximizes energy efficiency and reduces waste, making it both a cost-effective and environmentally friendly option. Whether you’re producing delicate vegetables, meats, fish products, grains, egg products, burgers, hams, Thermix™ guarantees that the food is cooked evenly every time.

The Thermix™ system, known as “The Original Sous Vide Cooking System,” is particularly suited for facilities needing consistent, high-quality results. It features continuous water circulation, which ensures uniform cooking/chilling and optimal heat transfer. This method maximizes energy efficiency and reduces waste, making it both a cost-effective and environmentally friendly option. Whether you’re producing delicate vegetables, meats, fish products, grains, egg products, burgers, hams, Thermix™ guarantees that the food is cooked evenly every time.

The Flowmatix™ system takes sous vide processing a step further by offering in-package pasteurization for ready-to-eat products. The fully continuous automated system reduces the need for manual loading and unloading, ensuring a constant flow of products through the cooking and chilling phases. With its compact design, Flowmatix™ is capable of producing between 1 to 4 tons of product per hour while using less space than other systems on the market. This flexibility allows food processors to scale production without sacrificing product quality or consistency.

In addition to sous vide processing, Middleby integrates complementary technologies like shock freezing and blast chilling. These tools enable food manufacturers to quickly chill or freeze products, preserving both quality and extending shelf life, which is critical for large-scale distribution. This comprehensive approach provides a complete solution, from cooking to preservation.

Post-sale, Middleby continues to support its clients through robust service offerings. With 24/7 customer service, digital monitoring tools, and access to service audit reports, manufacturers can optimize their operations and ensure that their equipment runs smoothly. Middleby’s RapidVisionPak also integrates with their sous vide systems, offering seamless packaging solutions that further enhance efficiency and product safety.

By combining cutting-edge technology with reliable post-sale service, Middleby ensures that its clients have everything they need to produce high-quality, consistent, and safe food products at scale. Whether you’re producing for foodservice or retail, Middleby’s solutions help manufacturers keep pace with consumer demand while maintaining the highest standards of quality.

Experience innovation firsthand. Witness the latest advancements in sous vide processing technology. Schedule your visit to the Middleby Protein Innovation Center now!

Topics

- Bakery ()

- Case-Ready ()

- Bacon ()

- Sous Vide ()

- Poultry ()

- See All Topics