Evolution and Innovation in Biscuit & Cracker Manufacturing – From Ships’ Biscuits to Middleby’s Complete Line Solution

The history of biscuit and cracker manufacturing is as rich as the products themselves. Originating in ancient civilizations as flatbreads baked for sustenance, biscuits evolved during the Middle Ages with the addition of sweeteners and spices—becoming a durable staple for long journeys. Fun fact: the word “biscuit” comes from the French bis-qui, meaning “twice-cooked,” referring to the original method used to extend shelf life.

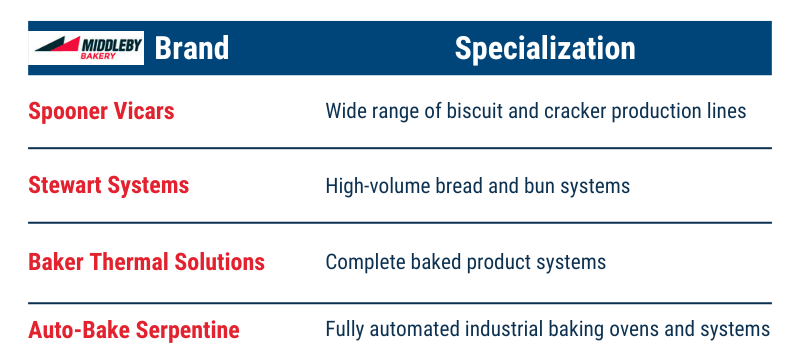

From small European bakeries to large-scale operations in North America, manufacturers face the challenge of efficiently producing consistent, food-safe, high-quality products that align with local tastes and meet regulatory standards. This need for precision, preferences, and hygiene has driven innovation in industrial baking—led by Middleby Food Processing and its family of trusted brands, like Spooner Vicars, known for their high-speed, precision baking solutions.

Innovations in Industrial Baking with Middleby

Modern biscuit and cracker manufacturing is a global enterprise. Middleby Bakery offers advanced solutions tailored to regional markets—from classic tea biscuits to protein-packed energy bars. Their automated lines and efficient dough-handling systems ensure consistency, flexibility, and throughput. Middleby’s commitment to innovation and flexibility positions it as a key player in shaping the future of industrial cookie machines and cracker manufacturing processes worldwide

Adapting to Global Markets

Adapting to global marketplaces demands innovative solutions that accommodate varying regulations, ingredients, tastes, and environmental conditions. To address these challenges, the Middleby Bakery provides comprehensive industrial baking equipment solutions that include advanced cookie and cake manufacturing equipment, fully automated production lines, oven systems, efficient dough handling systems, and many other processes that bakery producers require.

Middleby’s equipment is designed to ensure that manufacturers can produce high-quality products tailored to local tastes and preferences. This adaptability is crucial, as products worldwide are manufactured in slightly different ways depending on cultural tastes, environment, and preferences.

The Biscuit and Cracker Manufacturing Process

Biscuit and cracker manufacturing requires precision at every step to ensure consistent quality. The process begins with mixing, where ingredients are combined to create uniform dough or batter, forming the foundation for the final product. Feeding systems then guide the mixture through the production line with efficiency and accuracy.

Next, laminating and sheeting create the layers and textures vital for puffed biscuits and crisp crackers. Cutting and molding equipment shapes the dough into precise forms, while advanced techniques like wire cutting and extruding allow for intricate designs and product variety.

Middleby’s cutting-edge equipment integrates these steps seamlessly, offering efficiency and precision while meeting the diverse needs of global manufacturers. With innovative full-line and turnkey solutions, Middleby ensures exceptional product consistency and scalability.

Key Goals in Modern Biscuit and Cracker Manufacturing

- Reducing potential hazards with hygienic designs: Middleby’s equipment is designed for easy cleaning and maintenance, minimizing contamination risks and addressing challenges like mold growth in dough-based production. Although the ship biscuits from Spooner Vicars’ past may not meet today’s food safety standards, our modern designs address historical hazards and reflect our commitment to continuously innovating manufacturing practices to overcome future challenges.

- Reducing Downtime with parts and service:Innovative production lines by Middleby Bakery help eliminate costly downtimes with parts and services readily available to customers globally. As a result, new innovative designs and a commitment to accessible parts can take inefficient parts and service turnovers and reduce them by at least one-quarter of the time.

- Reducing waste with accuracy: One of the biggest roadblocks to profitability on a biscuit and cracker manufacturing line can be wasted product. Consistency and speed are vital for minimizing waste, and Middleby’s innovative designs ensure scrap-less production lines, boosting profitability.

Middleby’s Collaborative Approach

Middleby Bakery’s collaborative ethos leverages expertise across its brands, providing customized solutions that meet unique customer needs. This approach ensures that manufacturers can confidently deliver high-quality products while adapting to evolving market demands. The collaboration among sister companies, including Spooner Vicars, fosters innovation and reliability.

A Historical Snapshot: From Ship’s Biscuits to Modern Manufacturing

The Industrial Revolution transformed biscuit production through mechanization, introducing steam-powered ovens and mass production techniques. Iconic ship’s biscuits—once essential for long sea voyages and even foundational for pet food manufacturing—set the groundwork for today’s industrial methods. This legacy lives on through Middleby Bakery’s Spooner Vicars brand, a pioneer in efficient, hygienic biscuit and cracker production since 1849.

Spooner Vicars: History Informing Present Production

Spooner Vicars, with 175 years of history, started in 1849 by two brothers in Liverpool who manufactured ship biscuits. Their goals have always been the same—more efficient and hygienic production and cost-effective investments to implement it.

The goal of product diversity is still expressed in equipment innovations that can produce items ranging from sweet breakfast pocket snacks to famous cheese-flavored crackers. Middleby, Spooner Vicars, and other Middleby Bakery brands are known for their collaborative efforts to meet customer production goals. These conversations and goal-setting arrangements are always centered around reliability and food safety, core tenets of Middleby Bakery. Coupled with a commitment to innovation and flexibility, Middleby Bakery leads the way in the evolution of industrial cookie machines and cracker manufacturing processes worldwide—without ever forgetting that success in the future is rooted in the lessons of the past.

Explore More with Middleby Bakery

The biscuit and cracker manufacturing industry has come a long way, adapting to diverse global needs and embracing innovative technologies. Middleby Food Processing’s bakery division, with its rich history and commitment to customer-driven solutions, has played a pivotal role in shaping this the future of bakery production. Their focus on hygiene, efficiency, and waste reduction has helped manufacturers worldwide produce high-quality products while safely meeting local preferences and regulations.

Looking ahead, the industry is poised for further growth and innovation. Middleby’s collaborative approach, leveraging expertise across its brands, positions it well to tackle future challenges. As consumer demands continue to evolve, manufacturers who prioritize flexibility, food safety, and efficiency will be best equipped to thrive in this dynamic market.

Topics

- Bakery ()

- Case-Ready ()

- Bacon ()

- Sous Vide ()

- Poultry ()

- See All Topics