Addressing the Top Three Concerns of Hot Dog and Sausage Processing

The sausage processing equipment industry has undergone significant changes in recent years, driven by the need to mitigate labor challenges that were accentuated by the COVID-19 pandemic. With these challenges also come solutions, and Middleby’s Food Processing division has changed the face of the industry with a series of technological advancements. This has allowed manufacturers to better focus on automation, precision, and sustainability.

From state-of-the-art blending machines to advanced thermal processing systems and packaging technologies, the entire hot dog processing line is being reimagined. These cutting-edge developments enhance product uniformity and food safety but also optimize resource utilization and reduce environmental impact. As a result, manufacturers are better equipped to meet the growing demand for high-quality sausages and hot dogs while maintaining profitability in an increasingly competitive market.

How Is the Sausage Made?

The sausage and hot dog production process is a science that involves a series of carefully controlled steps. When the raw meat comes off the animal, it is weighed, blended, emulsified, and chopped. The prepared meat mixture is then stuffed into casings, cooked, packaged, boxed, and loaded onto trucks for distribution. Many different sausage processing equipment brands contribute to the various stages of the production line.

Middleby, through its sister companies and industry partners, offers solutions for each stage of the production line. Some of the world’s leading sausage and hot dog brands produce their products on sausage processing equipment from Middleby Food Processing.

The Principle Objectives of Sausage and Hot Dog Processing

The sausage and hot dog processing industry has three primary objectives: ensuring food safety, achieving process and product uniformity, and implementing green initiatives for sustainability. These goals are critical for manufacturers to maintain profitability and meet consumer expectations in an increasingly competitive market.

Food Safety Is Always the Top Priority

Food safety is the top priority in the sausage and hot dog processing industry. The more people involved in the production process, the greater the chance of contamination. To mitigate this risk, equipment innovations that reduce the number of required staff members not only increase efficiency and profitability but also reduce the likelihood of contamination during production.

If a product has to pass through seven conveyors to reach its final point, each person involved in the process should be treated like an additional conveyor – another touch point where contamination could occur. By implementing smarter, more simplified processes and automating key stages, manufacturers can minimize human contact with the product and enhance food safety.

Process and Product Uniformity Equals Profitability

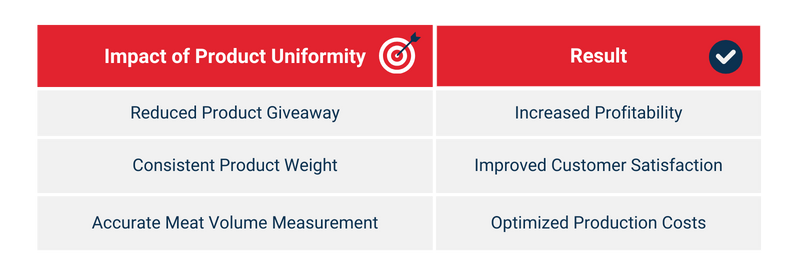

Process uniformity and product uniformity are critical to success in sausage and hot dog production. When these objectives are successfully met, manufacturers’ profits increase.

Product uniformity helps reduce “giveaway” by accurately measuring the volume of meat within each product. For example, a one-pound hot dog should weigh exactly one pound, not a few ounces more or less. Less product giveaway translates to higher profitability for the manufacturer.

Uniformity in the process and product also leads to consistency for the consumer. Customers expect the same quality and taste each time they purchase a particular brand of sausage or hot dog. By maintaining strict process uniformity, manufacturers can ensure that their products meet these expectations every time.

Ultimately, process uniformity leads to product uniformity. And product uniformity is the quickest way to customer satisfaction and profitability.

Green Initiatives and Sustainability Provide Many Benefits

In addition to food safety and uniformity, the sausage and hot dog processing industry is increasingly focusing on green initiatives and sustainability. Manufacturers are implementing various strategies to reduce their environmental impact and improve energy efficiency, including:

- Transitioning to electric ovens

- Improving insulation in processing equipment

- Reducing water consumption

- Lowering overall utility consumption

By fully insulating equipment cabinets with newer insulation materials that have better R-values and utilizing more efficient motors, manufacturers can significantly reduce energy waste.

Another example is the J-CON oven from ALKAR. Designed to maximize efficiency and product quality for hot dog and sausage manufacturers, it runs 24 hours a day, five days a week, with just three operators per shift. The J-CON reduces labor costs while ensuring fewer ends and tie-offs, which means less rework and higher product consistency. With increased uptime and enhanced yield, the J-CON is a reliable solution that delivers top-quality results every shift.

How Middleby Sausage and Hot Dog Processing Equipment Boosts Profitability

Middleby’s sausage and hot dog processing equipment innovations have significantly impacted profitability by reducing the number of people required to operate it. These advancements have changed the physical profiles of those needed to run a successful operation. Rather than relying on larger and stronger workers conducting manual labor, anyone can now operate the equipment using computers and tablets.

Upgrading Existing Lines for Maximum Profitability

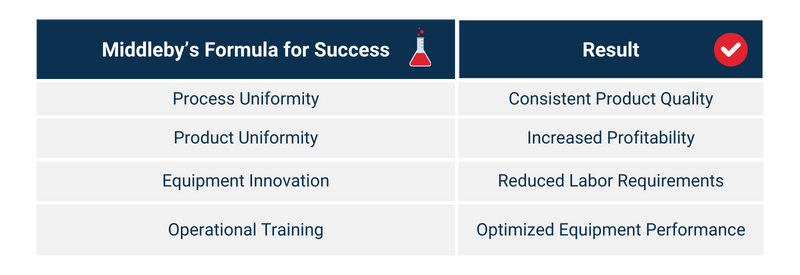

While Middleby excels at creating new production lines, it can also help existing lines that are incomplete or in need of upgrades, suggesting improvements that will maximize profitability by ensure process uniformity. This approach allows manufacturers to improve their existing infrastructure without needing a complete overhaul.

Global Presence and Scalability Testing

With a worldwide presence, Middleby serves customers across the globe. Manufacturers can leverage Middleby’s innovation centers to test the scalability of their products and processes, ensuring that they can meet the demands of their target markets.

Utility Monitoring and Operational Training

Middleby Food Processing offers utility monitoring services to help manufacturers optimize their energy consumption and reduce costs. They also provide operational training and classes onsite to ensure that personnel are well-equipped to handle the equipment and maintain process uniformity. In addition to training, Middleby conducts in-field audits on machinery to help operators get more out of their existing machines. This service is particularly valuable for manufacturers looking to improve efficiency and productivity without investing in new equipment.

A Formula for Hot Dog and Sausage Processing Success

Middleby Food Processing operates on the principle of “innovation on a foundation of expertise.” Their training staff has a wealth of experience, making them true experts in the field. The formula for success lies in maintaining process and product uniformity, which Middleby’s equipment and services are designed to deliver.

Middleby’s commitment to innovation on a foundation of expertise has resulted in groundbreaking solutions that address the top concerns of the industry. By focusing on process and product uniformity, food safety, and sustainability, Middleby is helping manufacturers boost profitability while meeting the growing demand for high-quality products. Put another way, Middleby is making the world a better place “one hot dog at a time” by harnessing the expertise, passion, and dedication that drives the industry forward.

Experience innovation firsthand. Witness the latest advancements in hot dog and sausage processing technology. Schedule your visit to the Middleby Protein Innovation Center now!

Topics

- Bakery ()

- Bacon ()

- Sous Vide ()

- Poultry ()

- Hot Dog and Sausage ()

- See All Topics