The Formula for Industrial Sweet Goods Profits

Industrial sweet goods and bakery profits hinge on a carefully calculated formula. Producing industrial sweet goods like celebration cakes, snack cakes, cheesecakes, steamed cakes, cupcakes, muffins, brownies, cookies, and pies demands precision, efficiency, and innovation. Industrial baking equipment plays a crucial role in this process, shaping the future of large-scale bakery operations and driving profitability in an increasingly competitive market.

Middleby Bakery understands that while the formula retains the same basic components, it can differ depending on the goals. From industrial baking equipment that delivers the top return on investment in the industry to more traditional methods, the idea of “FlexAgility” can be game-changing in modern baking lines.

What does that mean? Let’s start with the latest innovations.

The Benefits of Serpentine Industrial Baking Equipment

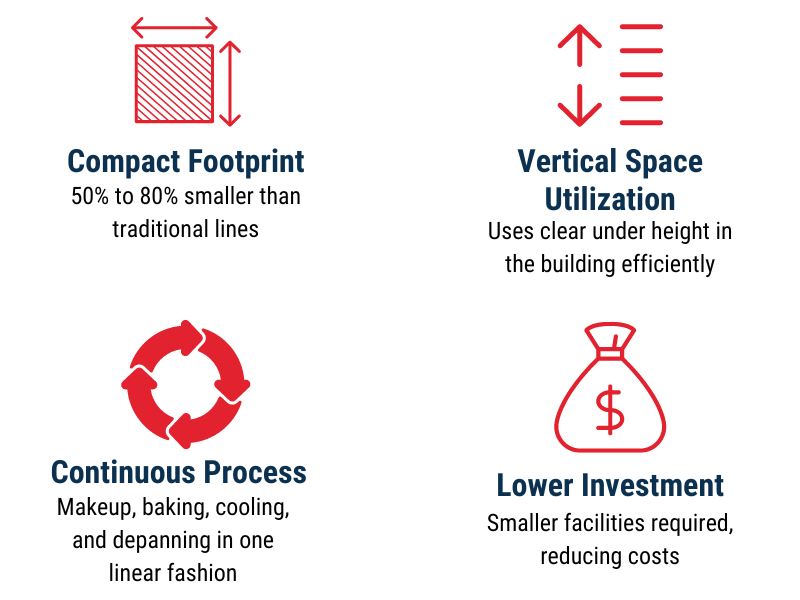

Middleby Bakery, through its Auto-Bake Serpentine brand, offers the largest industrial bakery throughput in the smallest footprint across the globe. This is achieved through the innovative serpentine design of its industrial baking equipment. Full-line Serpentine Baking Systems occupy between 50-80 percent less space than conventional baking equipment lines.

The compact footprint of serpentine systems allows producers to achieve production in small, underutilized spaces within existing facilities, maximizing both space and return on investment. This yields significantly lower costs in the long run. Auto-Bake’s ongoing R&D and market understanding, combined with the inherent flexibility and modularity of their system, enable them to be highly responsive to changing trends in baked goods supply and consumption.

The serpentine design provides the highest production output for the footprint used, which is a significant advantage in today’s competitive market. By occupying less space, producers can reduce their facility costs and optimize their production processes.

How Does a Serpentine Design Work?

The system’s conveyors move pans and product through a HORIZONTAL serpentine pathway throughout each of the baking system modules, maximizing the available height in a space and minimizing the overall footprint of the system. Unlike conventional methods, this innovative design enables continuous production, and the system’s modularity allows for customization to meet specific needs.

One key advantage of the serpentine design is its labor efficiency. A single operator can handle up to five production lines at the same time, significantly reducing labor costs. Inherent to Auto-Bake’s Serpentine design is the precision that thermal energy is supplied directly and independently to the top and bottom of the product throughout the process. This is compared to a conventional system where energy is supplied indiscreetly between the top and bottom of the product and from the perimeter. The combination of consistency and efficiency makes the serpentine design an unrivaled tool in industrial baking, but those aren’t the only benefits.

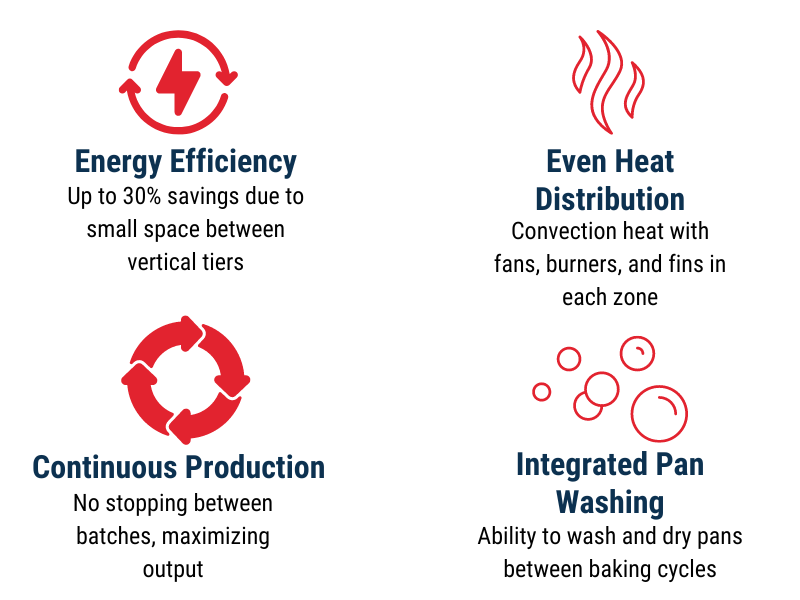

The convection heat system includes a fan and burner in each zone and fins to disperse the air evenly. This ensures that the energy hits the product optimally, leading to superior baking results. The serpentine design also conserves heat due to the small space between the vertical tiers, resulting in up to 30 percent energy savings compared to traditional industrial baking lines.

Additionally, the system can include an integrated pan washer, allowing for the washing and drying of pans between baking cycles. This feature minimizes downtime and enhances overall efficiency, underscoring the turnkey nature of the serpentine design.

“FlexAgility”

Middleby Bakery has coined the term “FlexAgility” to describe the unique adaptability of its industrial baking equipment. This concept includes the ability to produce a wide range of industrial sweet goods on the same production line, offering unparalleled flexibility of product range coupled with the agility of speed between product changeovers.

Auto-Bake’s serpentine systems are designed to accommodate quick changeovers between different product types. Producers can switch from baking cakes to muffins, cookies, or other sweet goods in as little as 15 to 30 minutes. This short downtime between production runs enables bakeries to manage multiple SKUs and efficiently respond to changing market demands.

The modular design of Auto-Bake’s equipment allows for the customization of baking parameters, ensuring optimal results for each product. This flexibility is particularly valuable for companies with diverse product portfolios or those catering to emerging markets with varying consumer preferences.

In addition to its cutting-edge serpentine solutions, Middleby Food Processing also offers traditional industrial baking equipment. This comprehensive approach positions Middleby as the go-to source for all industrial sweet goods baking needs, providing operators with the best technology in the industry while also accommodating those who require conventional baking capacities.

The Advantages of Working with Middleby’s Industrial Sweet Goods Category within the Bakery Division

Partnering with Middleby Bakery offers significant advantages with respect to faster startup times, comprehensive support services, and long-term operating cost savings. Producers can expect a 20-40 week faster startup time compared to competing baking equipment manufacturers, enabling them a much faster payback. Standard designs are available in as short as 12 weeks with Auto-Bake “On-Demand” lines, and custom designs are available in as little as 30 weeks. If Auto-Bake isn’t the right fit for a particular application, Middleby has a matrix of alternative options to suit nearly any customer requirement.

Middleby’s extensive support network includes several test facilities where producers can both demo the technology before purchasing and wet test their line before shipping. With a large global service team, Middleby offers remote service within 8 hours and onsite support between 24 and 48 hours. New production lines include four visits in the first year, and additional training for new hires is available year-round to combat high turnover rates.

By considering Middleby as an extension of their own service teams, producers can navigate the challenges of labor shortages and ensure optimal equipment performance. Middleby Bakery’s commitment to partnership and support is a differentiating factor in today’s sweet goods manufacturing marketplace.

Experience innovation firsthand and witness the latest advancements in baking technology. Schedule your visit to the Middleby Bakery Innovation Center now!

Topics

- Bakery ()

- Bacon ()

- Sous Vide ()

- Poultry ()

- Hot Dog and Sausage ()

- See All Topics